We are proud to announce the acquisition of A&B Richardson Engineering, which will continue to operate under the A&B Richardson Engineering name.

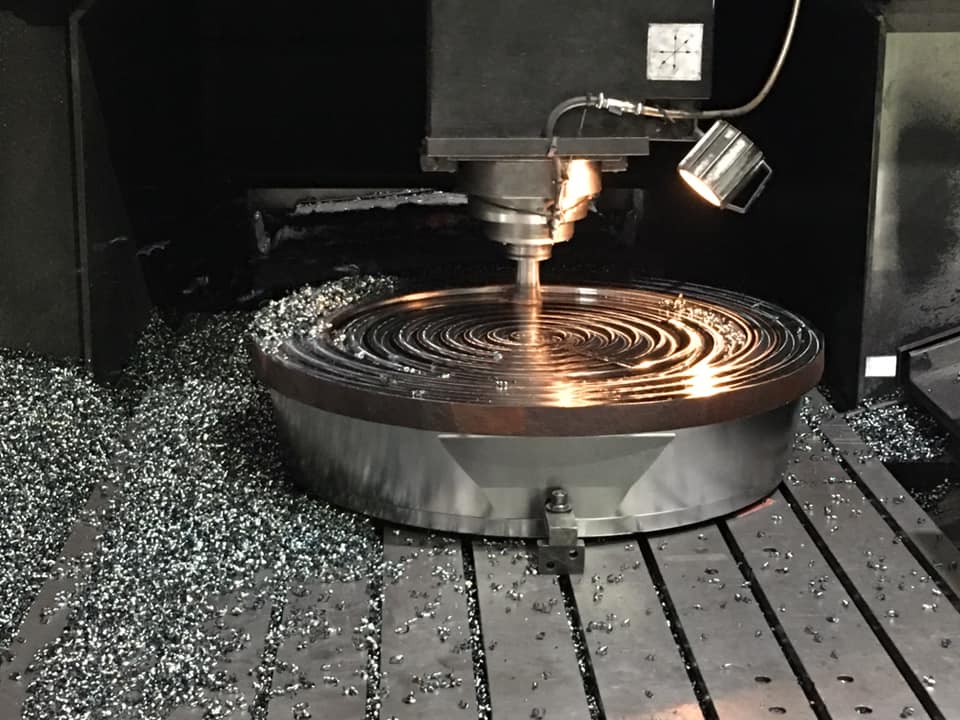

This deal will allow us to build upon current machining capabilities, with it tripling our CNC machining capacity! A&B Richardson Engineering based in Oldbury, and is a leading tool and die manufacturer. They have continually invested in a variety of CNC machines, CAD design capabilities and also new welding capabilities.

The acquisition of the machine shop is part of the Somers Forge long term strategy to expand machining capacity and capabilities after seeing increased demand for finished components. The established machining facility and long serving experienced machinists provides immediate capacity for fulfilling the recent order book growth. A&B Richardson has been a trusted sub-contract machining facility, used by Somers Forge for many years.

Alex Cross, Production Director said “Last year we made a million-pound investment on a new CNC vertical boring machine which will help us to manage capacity for that range of product. We also recognised the need for greater capacity with CNC milling so the acquisition of A&B Richardson was the perfect solution. The purchase has tripled our CNC machining capacity and further enhanced our capabilities, allowing us to continue to offer competitive lead times and products of the highest quality’’.

Welcome A&B Richardson Engineering to the Somers Team!