Forged Turbine Shafts

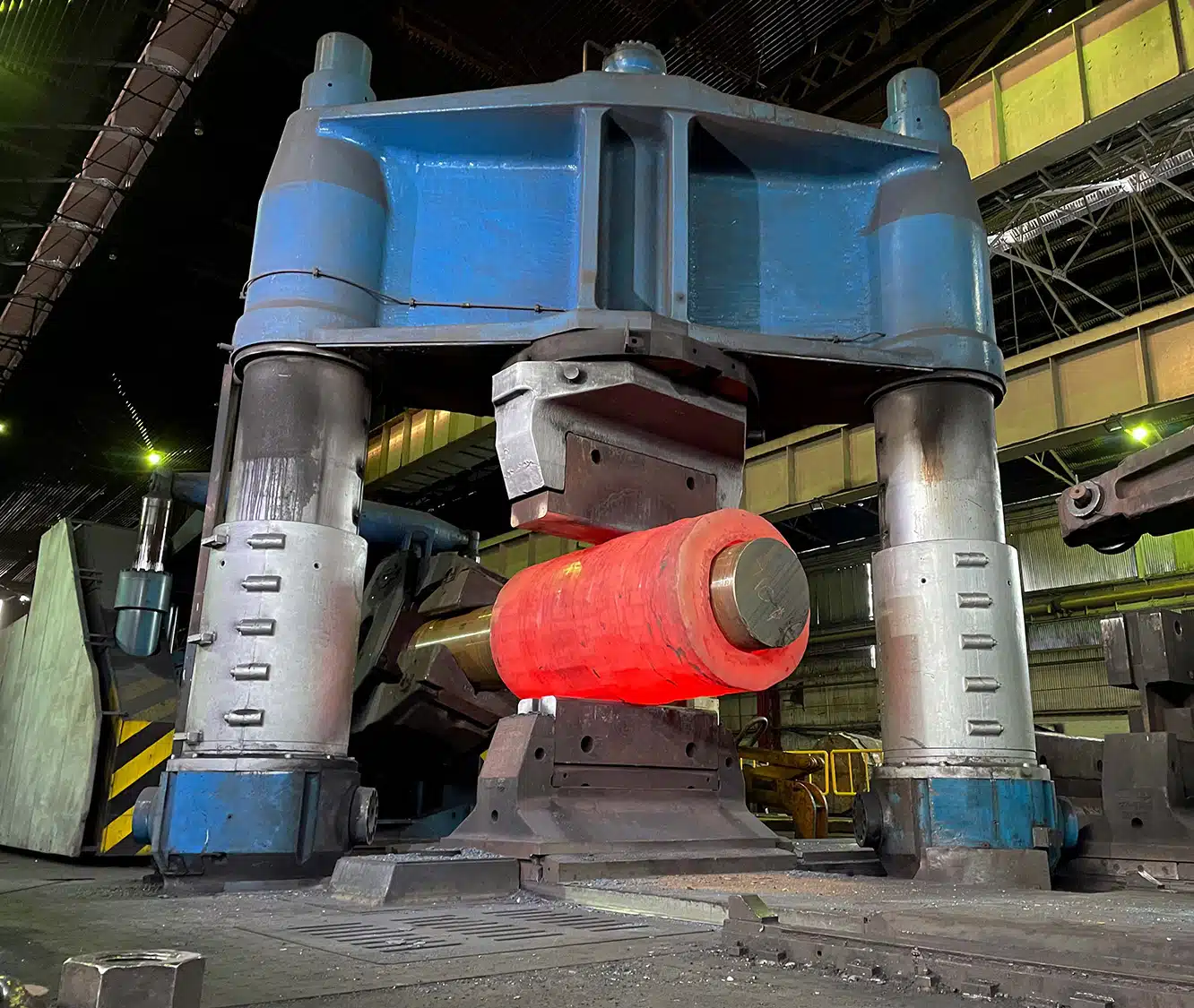

We are keen on making a difference. With inhouse facilities and a skilled workforce we supply power generation forgings for the renewable energy sector, including hydroelectric power, tidal/wave or geothermal energy, wind and biomass power.

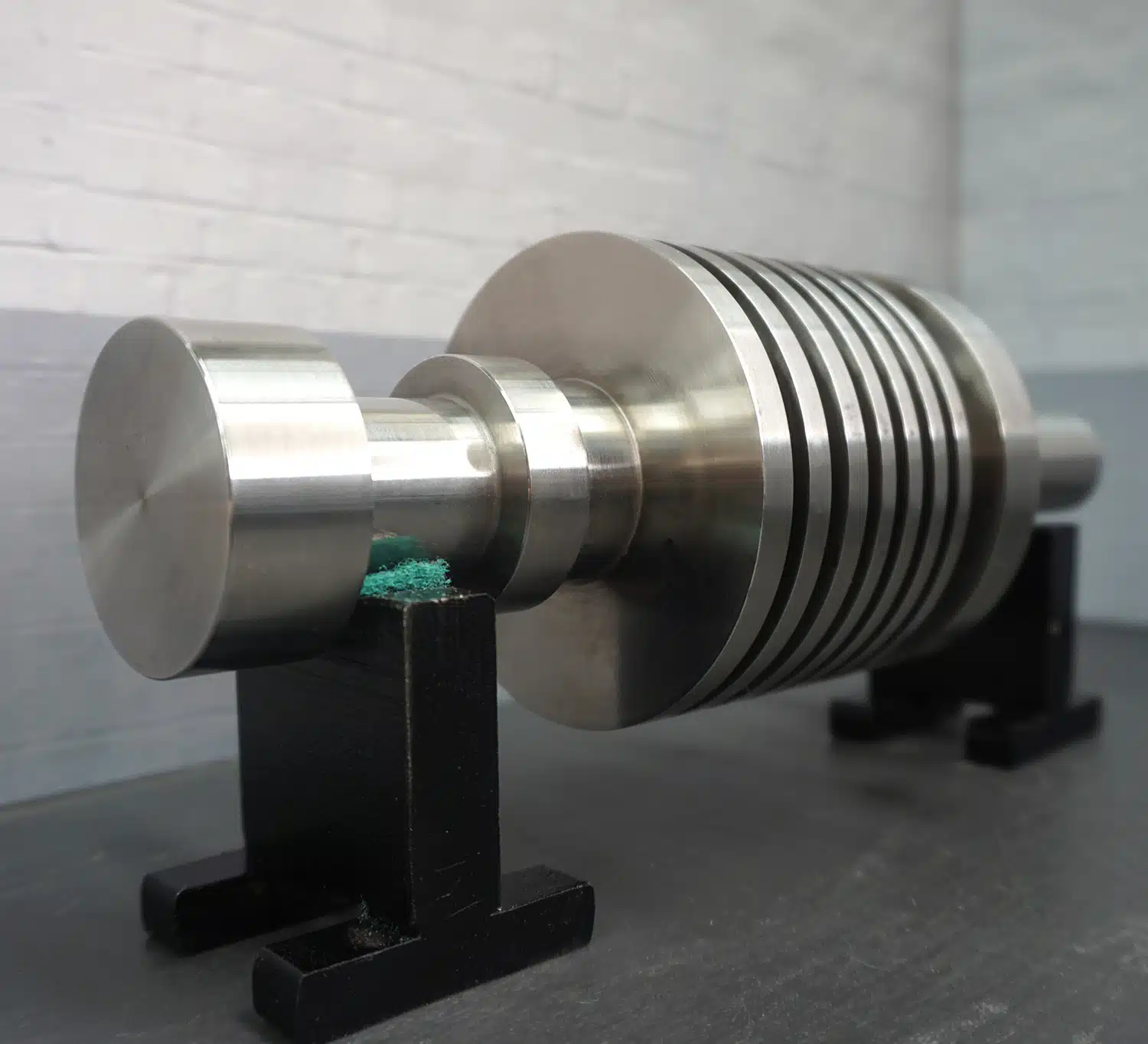

We offer a range of forged shapes for turbines along with generators, compressors, gear boxes, heat exchanges and blowers. Suppling turbine shafts connecting the turbine to the generator, with the shaft turning at the same speed as the actual turbine. This requires turbine shafts to be from the highest quality forging. We manufacturer turbine shafts and low speed shafts according to the customer requirements, up to 23metres in length.

Common material grades used in the power generation sector include 18CrNiMo7-6, AISI 4340, 17-4PH, X750, 718.