Machine up to 100 Tonnes

We can manufacture components in excess of 20 metres to the tightest of tolerances and turn up 100 tonnes. With 5 axis milling up to 80 tonnes.

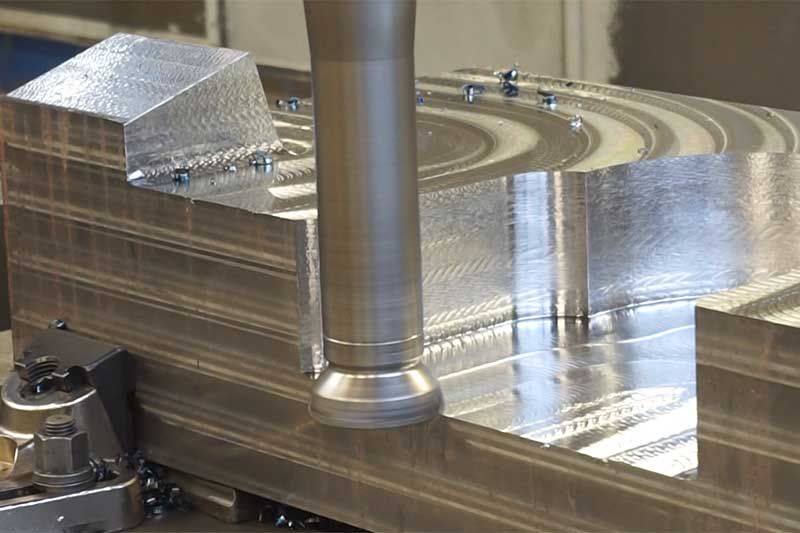

Equipped with

- Vertical Boring

- Horizontal Deep Hole Boring

- Honing

- Milling

- Turning

- Drilling Machines

- Balancing

- Sawing