Increasing Product Lifespan

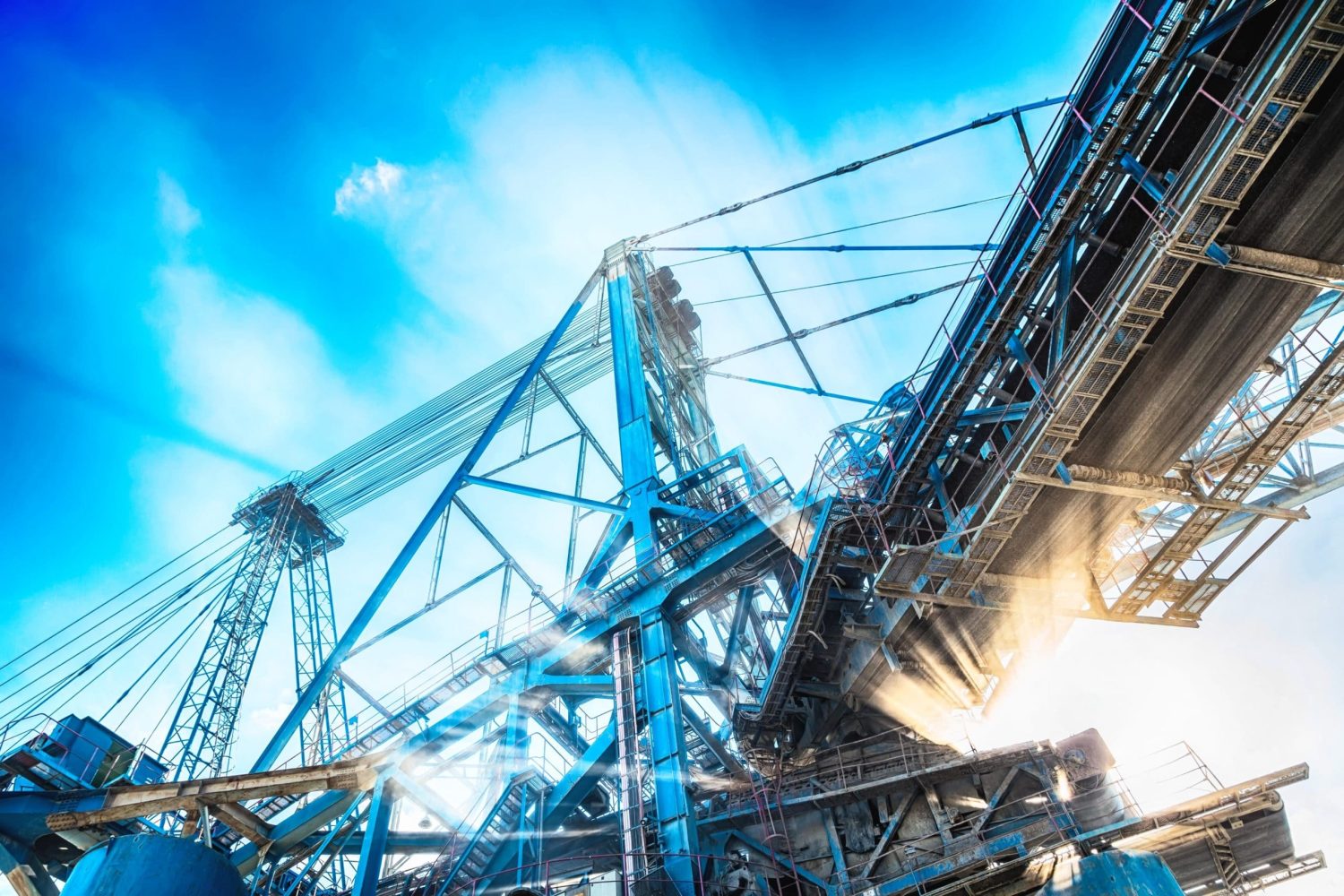

From forgings designed and created solely to perform sub surface right through to those for deep sea. Our team can offer all types of parts to ensure you continue digging around the clock.

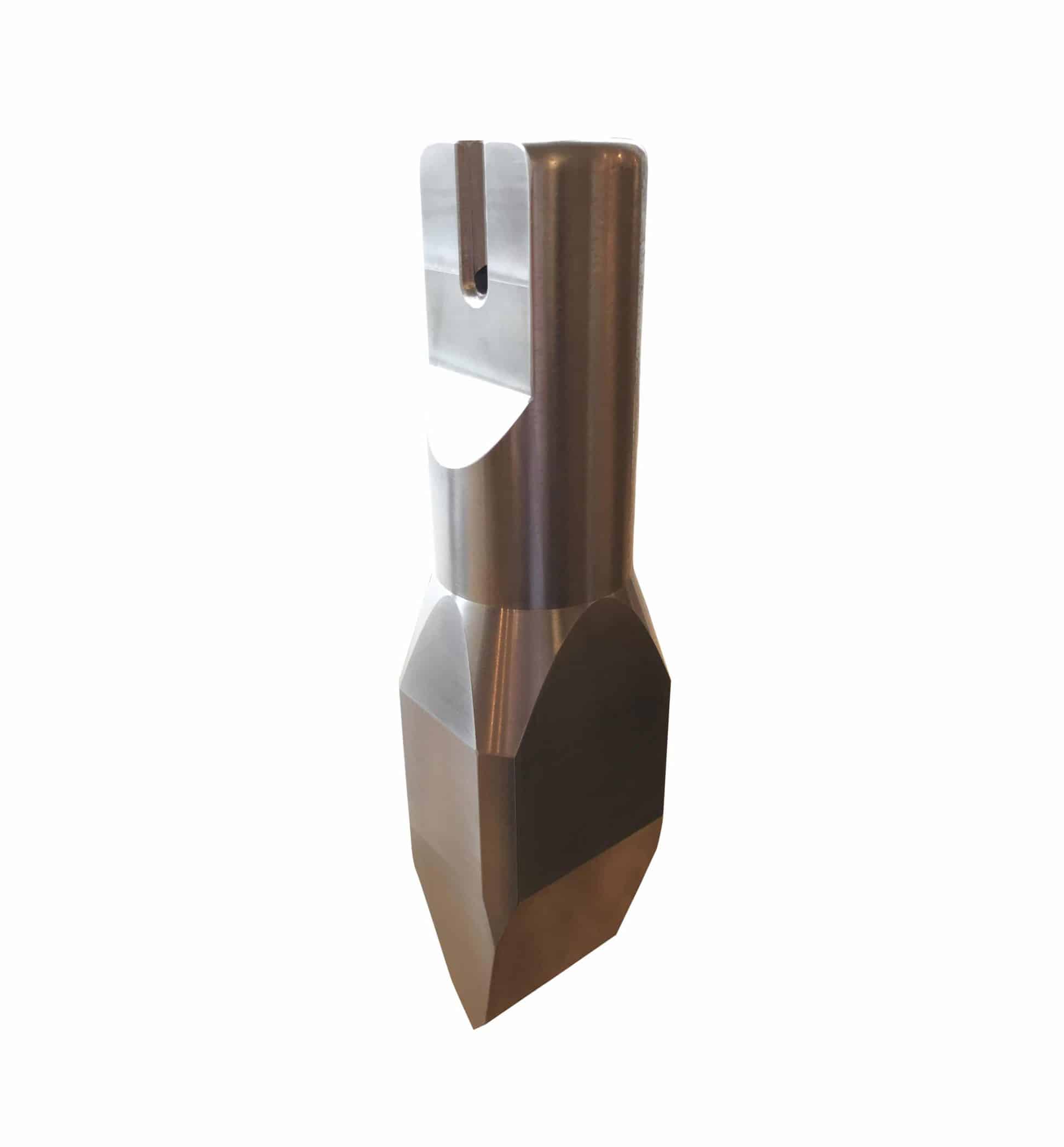

We forge a full range of quality crusher shafts, built to withstand the crushing of rock. Made from carbon steel and low alloys to be durable and cost effective.

We improve service life with custom made forgings for all your mining needs.