1697

We are proud to say that we are the 10th oldest family run firm in the UK, with it all starting back in 1697 with the pioneering Joseph Folkes and the Lye Forge

We are proud to say that we are the 10th oldest family run firm in the UK, with it all starting back in 1697 with the pioneering Joseph Folkes and the Lye Forge

We manufactured body armour and swords for the Battle of Blenheim in 1704

Our forging excellence resulted in a Royal Warrant from Queen Victoria

Our first hydraulic press was installed in 1895 with a 600 tonne capacity

Our growing workforce forged the Iron Cathead for H.M.S Goliath

Forging 84ft long shaft under 12 tonne hammer

Installed a 3,600 tonne steam hydraulic press

We forged and machined four 20 ft steel columns for the Bank of England

Somers swimming bath, which are in the works ground, were open to the public. Pictured on special gala day

11 ton anchor supplied for R.M.S Aquitania, we also forged parts for the anchors on the Olympic- class ocean liners (Titanic, Olympic, Britannic)

Instructions for telegraphing urgent orders in our old brochure

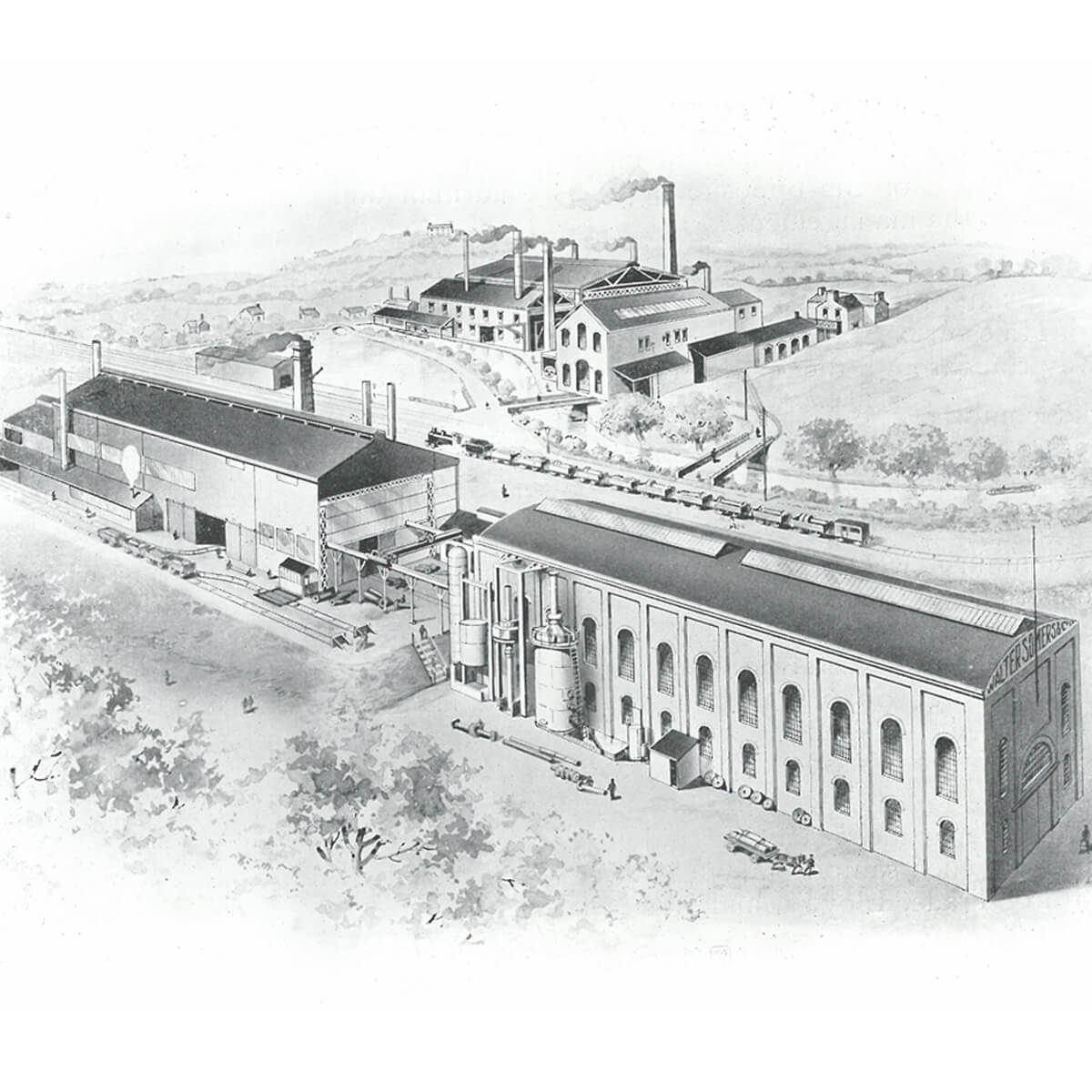

With business booming there was an extension of the steel building, now the Machine Shop

Throughout WW1 women played a hugely important role at Somers, including turning and boring shells for the war

Princess Victoria Louise the sister to King George visited the works

Forged steel ladle hooks to lift 100 tons

H.M. King George VI and Queen Elizabeth visit Somers at the British Industries Fair

Multiple-throw crankshaft for the marine industry

Somers Forge

23rd April H.M Queen Elizabeth II and Prince Phillip opened Press 6 which was very much ahead of it's time and exciting for Britain. Pictured here watching the forging.

Constantine Folkes became the youngest chairman of a public company in the UK at 28 years old. Now he is both chairman and chief executive of the Folkes Holding Company.

Somers Steel USA was established in 1983 to serve America's closed forging steel needs.

Controller of the Navy, Vice Admiral Sir Derek Reffell pictured during a visit to the Somers Machine Shop.

One of the many thank you letters from Ministry Of Defence for receiving our 'magnificent' book

Largest rock breaking chisel of it's time at 25 tonnes which is still in service today. A testament to the strength and longevity of Somers products.

Leading the TransForge Project, which examined the feasibility of fabricating dissimilar weld joints for nuclear power plants, to prevent the high failure rates

Somers rebranded our logo to "Forging a stronger future" to show our commitment to building a stronger future for British engineering

Somers have recently completed a 1.4 million pound update of our equipment and refurbishment of our medium sized Press

Investment in a new £1million Starrag CNC Vertical Borer to further increase capabilities and capacity

A&B Richardson Engineering was welcomed to the team. This acquisition expanded machining capacity and capabilities.

Our Vision

To set world class standards in forging and engineering whilst using an environmentally friendly process through investment in the latest technology for future generations

From our manufacturing facility in Halesowen, situated right in the heart of the industrial Black Country, we operate a varied range of Forging Presses and Hammers which gives us a unique capability to manufacture components from as little as 1 Kg to 80 tonnes with lengths up to 23 Metres.

Our Machining and Engineering facilities compliment the range of forgings we produce offering Turning, Boring and 5 Axis milling, which enables us to supply fully finished components ready for installation. We have the ability to machine products right up to 100 tonnes.

With continuous investment Somers combines the latest technology with traditional quality skills to compete and thrive in a very diverse global market. At first you may think you have never come across our products but from the deepest oceans to outer space our forgings are pushing the boundaries of manufacturing excellence!

Quality Assurance is at the forefront of all manufacturing processes, the company operates under a quality management system accredited to AS9100 Rev D, BS EN 9100:2015 and ISO 9001:2015. Ensuring all of products are delivered both right first time & on time.