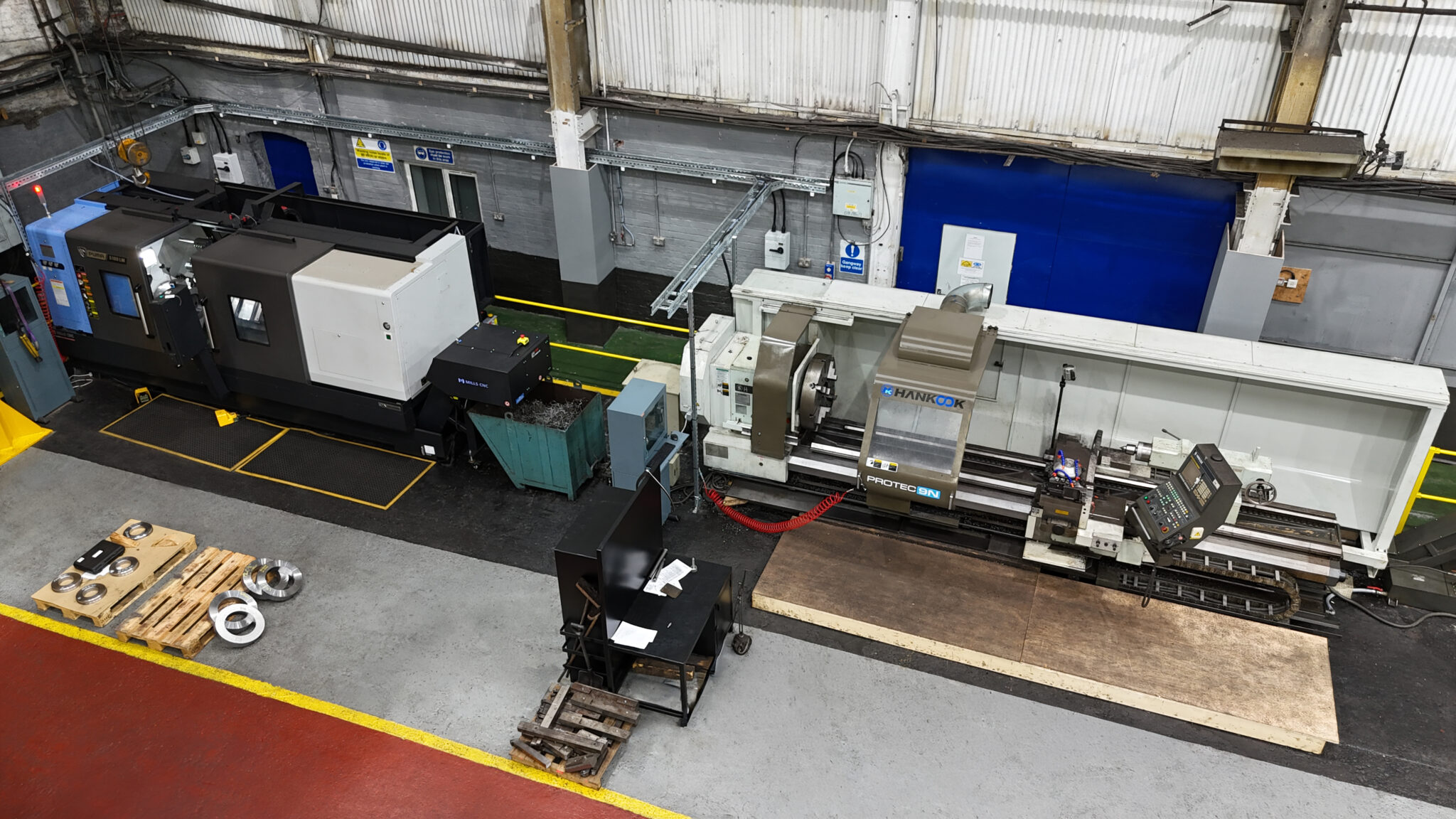

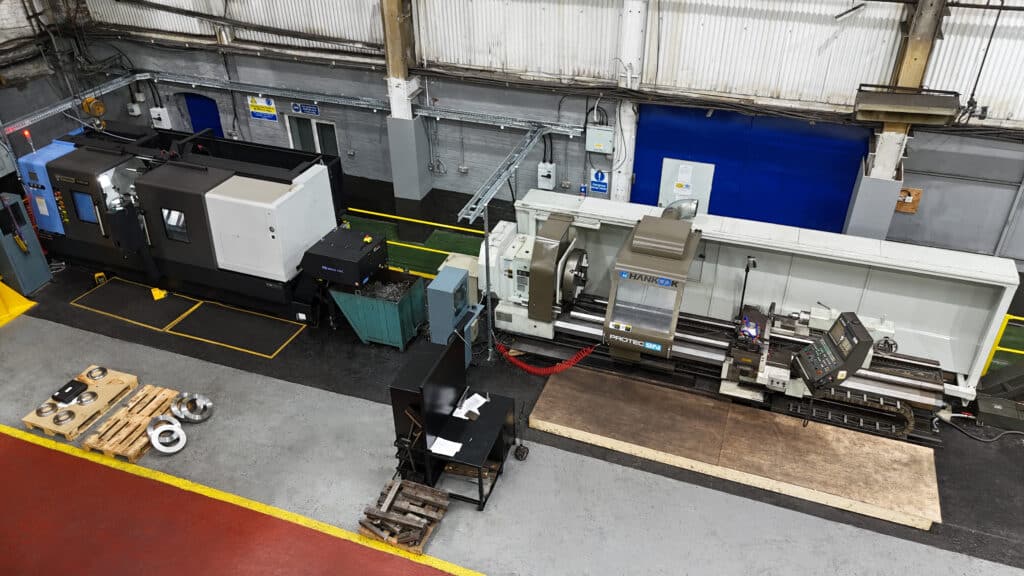

We are happy to announce the latest addition to our machining capability, two upgraded CNC lathes with integrated milling, designed to deliver exceptional precision, flexibility and productivity. This investment represents another important step in our ongoing commitment to continuous improvement and innovation, further strengthening our light forge capability with finish machining components up to 5 tonnes.

What Do Our New CNC Machines Include

Doosan Puma CNC Lathe: Capable of handling workpieces up to 690 mm in diameter and 2000 mm in length, this robust lathe supports a maximum weight of 5 tonnes.

Hankook Protec: Designed for even longer components, this lathe accommodates diameters up to 630 mm and lengths reaching 3845 mm, also supporting workpieces weighing up to 5 tonnes.

What This Means For Somers Forge

These solid lathes will enable us to handle increasingly complex parts that demand tighter tolerances. The integrated milling functionality means we can seamlessly combine turning and milling operations within a single setup. This not only boosts efficiency by reducing handling and set up times but also ensures greater accuracy throughout the machining process.

We are excited about the opportunities this latest upgrade brings, both in elevating our overall machining performance and in expanding the range of services we can offer our clients.

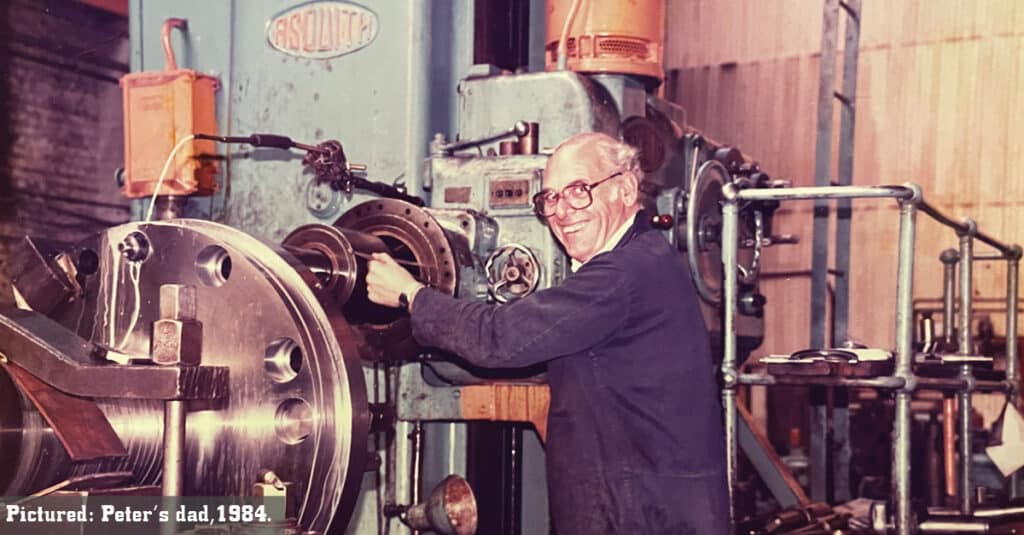

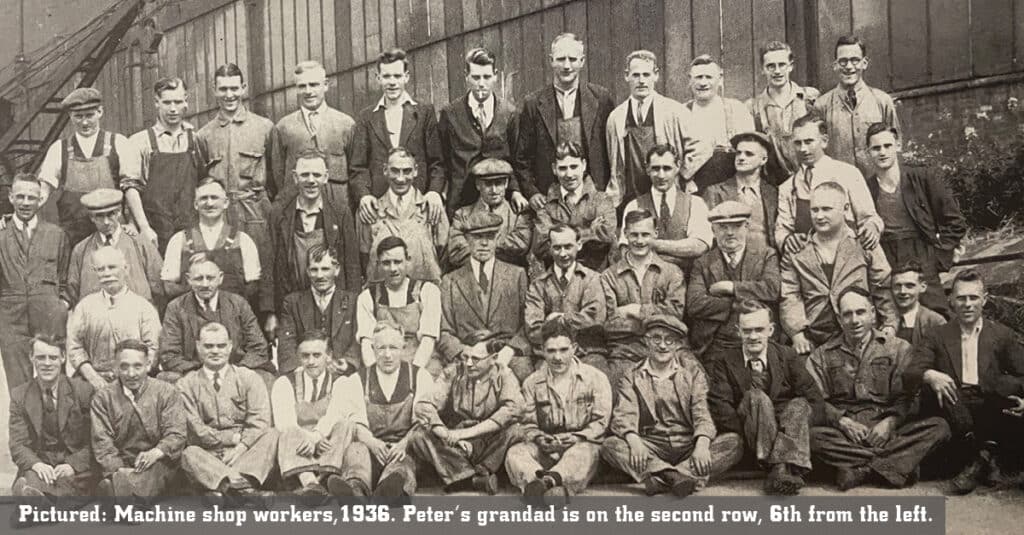

This important enhancement is a direct continuation of the momentum gained from our recent acquisition of A&B Richardson Engineering, a strategic move that resulted in a remarkable tripling of our CNC machining capacity. Such growth has already begun to transform both the scale and efficiency of our operations.

Our commitment to excellence drives us to keep investing in our in-house machine shop. Looking ahead, we have ambitious plans for further developments, including the addition of a much longer lathe spanning over 12 metres. This investment will enhance our capacity to support the finish machining of propulsion shafts.

By continuously expanding and upgrading our capabilities, we aim not only to meet but exceed client expectations, reinforcing our commitment to delivering superior results and building long term partnerships founded on trust and innovation.