Experts in Boat Propeller Shaft Manufacturing

At Somers Forge, we pride ourselves on being among the few forge masters capable of offering a comprehensive supply chain, including the finish machining of propulsion shafts for both fixed pitch and controllable pitch propeller (CPP) applications. Our state-of-the-art facilities, rich in history and equipped with the latest technologies, can manufacture components exceeding 20 meters in length. Our CNC lathes and unique boring facilities enable us to bore a shaft up to 20 meters from one direction only, ensuring perfect balance and no mismatch in the centre hole. This is essential for the propulsion shafts we supply for submarines, frigates, patrol vessels, super yachts, large vessels and icebreakers.

Propeller Shafts and Marine Propulsion Systems

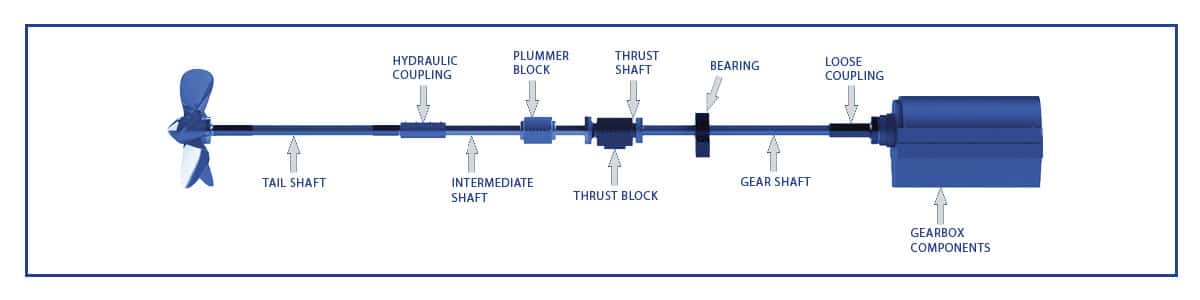

A boat’s propulsion system, essential for generating thrust and enabling navigation, comprises the main engine, gearbox, and propeller shaft. The propeller shaft is a crucial component, subjected to various loads such as torque moments, bending moments, axle thrust forces, and transverse loads. Weather and sea conditions can directly impact the wear and tear of propulsion shafts, increasing the risk of system failure. Therefore, emphasis on efficient propulsion shaft design and maintenance is critical.

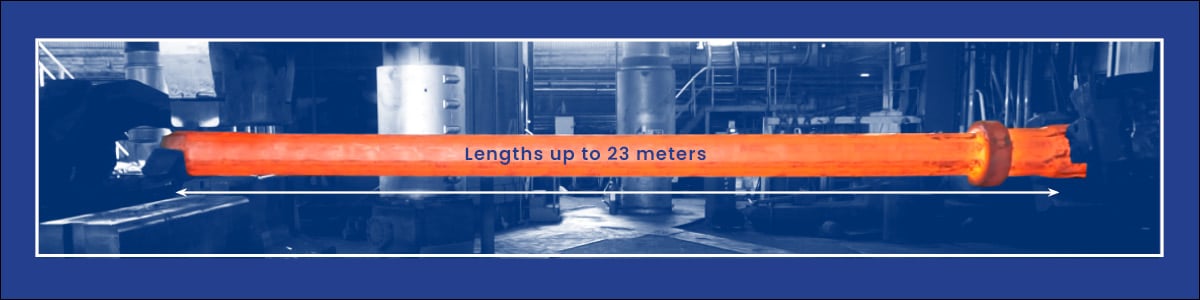

Boat Propeller Shaft Supply

We specialise in manufacturing boat propeller shafts in various sizes, up to lengths of 23 meters, tailored to your specific requirements. Our marine propulsion components cater to a range of vessels including submarines, naval ships, patrol vessels, super yachts and cruise ships. We primarily use materials such as C45, 34CrNiMo6, stainless steel, and inconel, but we can accommodate any material specified by our customers. In addition to shaft forging, we offer finished machining services to deliver ready to install propeller shafts.

Advanced Techniques for Enhanced Durability

To ensure the durability and performance of our propulsion shafts, Somers Forge employs advanced techniques and coatings. Our proprietary Glass Reinforced Coating, Somplas, offers superior protection against corrosion and impact. Rigorously tested and approved by DNV, ABS, and Lloyds, Somplas meets the highest industry standards and is REACH compliant, providing an environmentally friendly option for marine shaft coatings.

Weld Cladding for Extended Shaft Life

Recognising the harsh marine environment’s impact on propulsion shafts, we have invested significantly in weld cladding technology. This process enhances protection against seawater corrosion, extending the life of both stainless steel and nickel-based alloy shafts. As the first UK forge to offer this ABS-approved service, we are bolstering the nation’s shipbuilding capabilities, and ensuring the longevity of your propeller shafts.

Refurbishment Services for Boat Propeller Shafts

In addition to manufacturing new shafts, Somers Forge offers a class-approved procedure for refurbishing all types of propeller shafts. Our in-house developed refurbishment processes can return shafts to near ‘new’ condition, extending their operational life by up to 12 years, depending on the water environment. This service saves you time and money, while reducing the lifecycle analysis impact.

Comprehensive Marine Forgings and Support

Somers Forge has built a first-class reputation with many of the world’s navies, and is a preferred supplier to numerous OEMs. We provide comprehensive support and services for propulsion shafts. Our experts offer guidance and assistance throughout the entire process, from material selection to final installation, ensuring you receive the highest quality products tailored to your specific needs.

Why Choose Somers Forge?

Somers Forge stands out as a global leader in the supply of boat propeller shafts due to our:

Historical Pedigree: Over a century of experience in the marine industry.

Advanced Manufacturing: State-of-the-art facilities capable of producing components over 20 meters in length.

Innovative Techniques: Proprietary coatings and weld cladding technology for enhanced shaft durability.

Comprehensive Services: Complete supply chain from forging to finish machining and refurbishment.

Commitment to Quality: Adherence to the highest industry standards and approvals.

Whether you need new propeller shafts, propeller shaft refurbishment, or simply want some expert advice, Somers Forge is your trusted partner in marine forgings. Contact us today to discuss your specific requirements and discover how we can support your business’ needs.

Propulsion Shafts | Marine Industry | Propeller Shaft Forging | Weld Cladding Technology