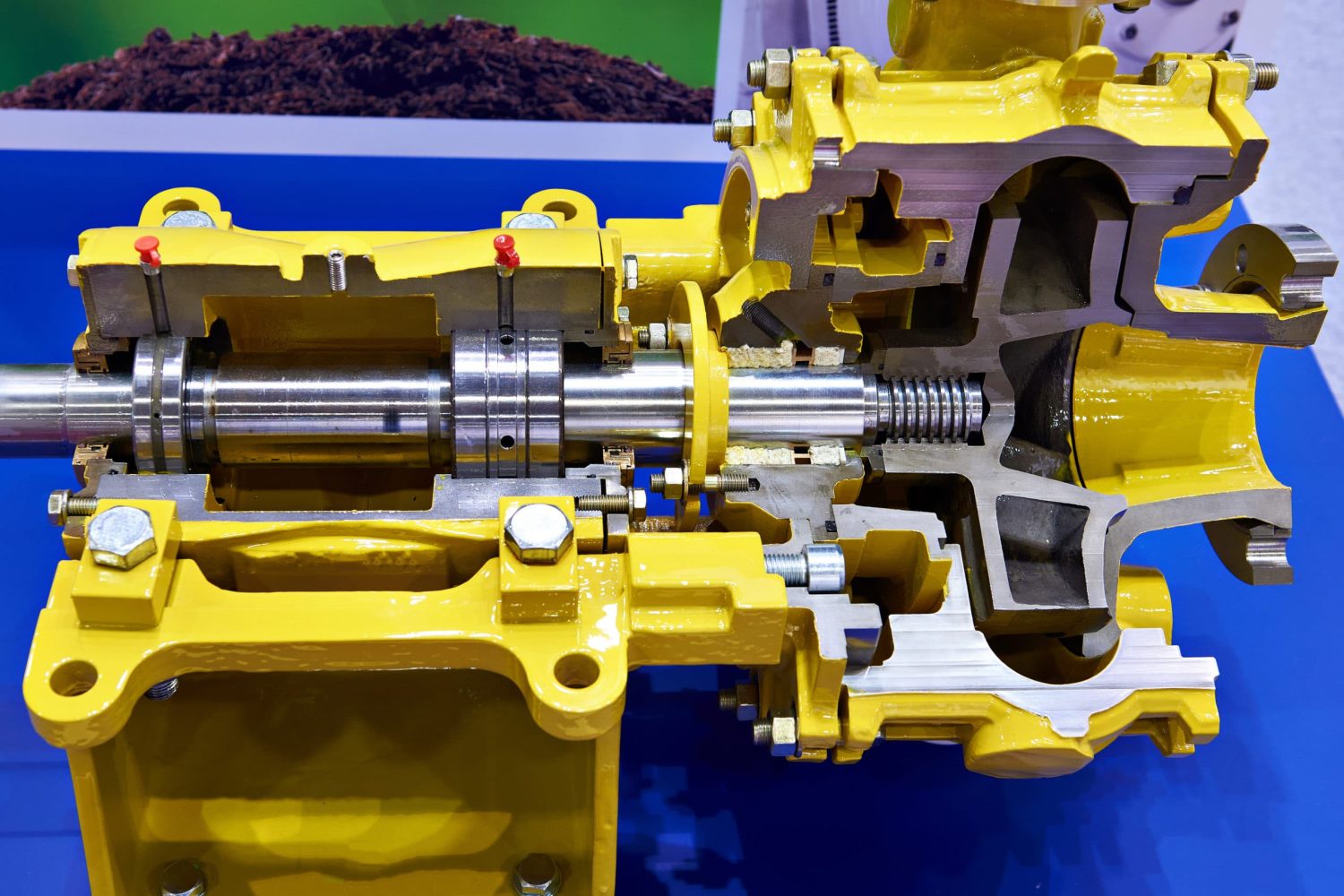

What is a turbine shaft used for?

The turbine shaft connects the turbine to the generator, turning at the same speed as the turbine. It is essentially an item that is used in machine designed for producing continuous power. The system it is used in basically extracts energy from a fluid flow and then converts it into a usable form or medium. You will often find large turbines in power generation sector, where they play a keep role in the successful running of these types of units.