Naval Forgings

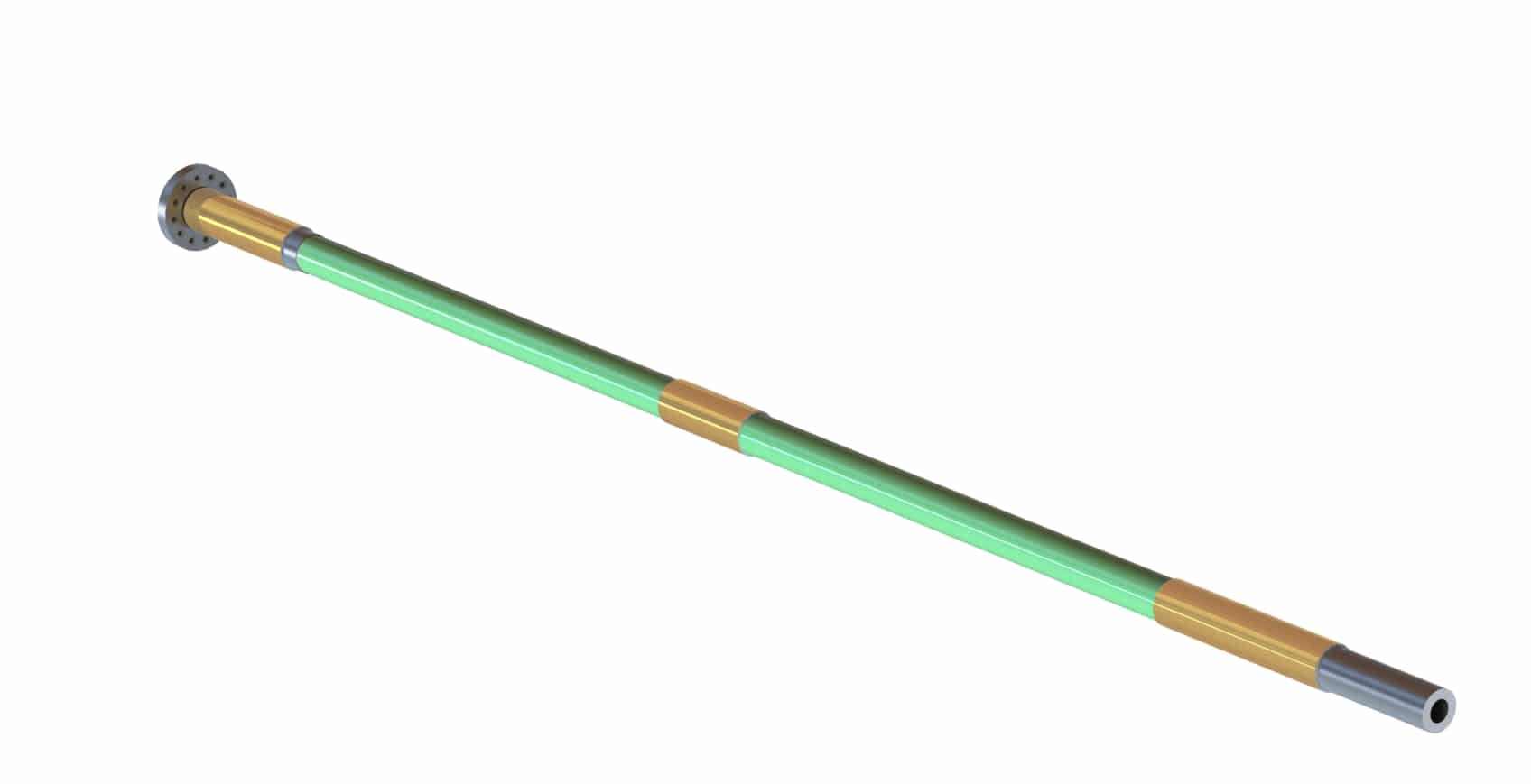

Somers Forge is a trusted supplier to the defence industry, manufacturing high grade steel products for more than 150 years. Specialising in open die forging for defence applications, manufacturing a range of bespoke products and spares for the world’s navy’s, air force’s and ground units. Our reputation from supplying over 15 global navies and proven capabilities goes without saying, as we are a first-class provider of marine defence forgings and finished components for frigates, destroyers, submarines and aircraft carriers to name a few.

As a world leader in open die forging, we have an unrivalled range of equipment in Europe, giving our customers greater flexibility and allowing us to produce forgings between 1kg up to 80 tonnes with lengths up to 23 metres. This caters for a large range of bespoke military parts from full shaft lines to small engine parts. We work with a range of materials including carbon steel, specialised nonferrous and super alloys for military applications including DefStan. Offering inhouse forging, heat treatment, machining, testing and even on site installation.