What is Open Die Forging?

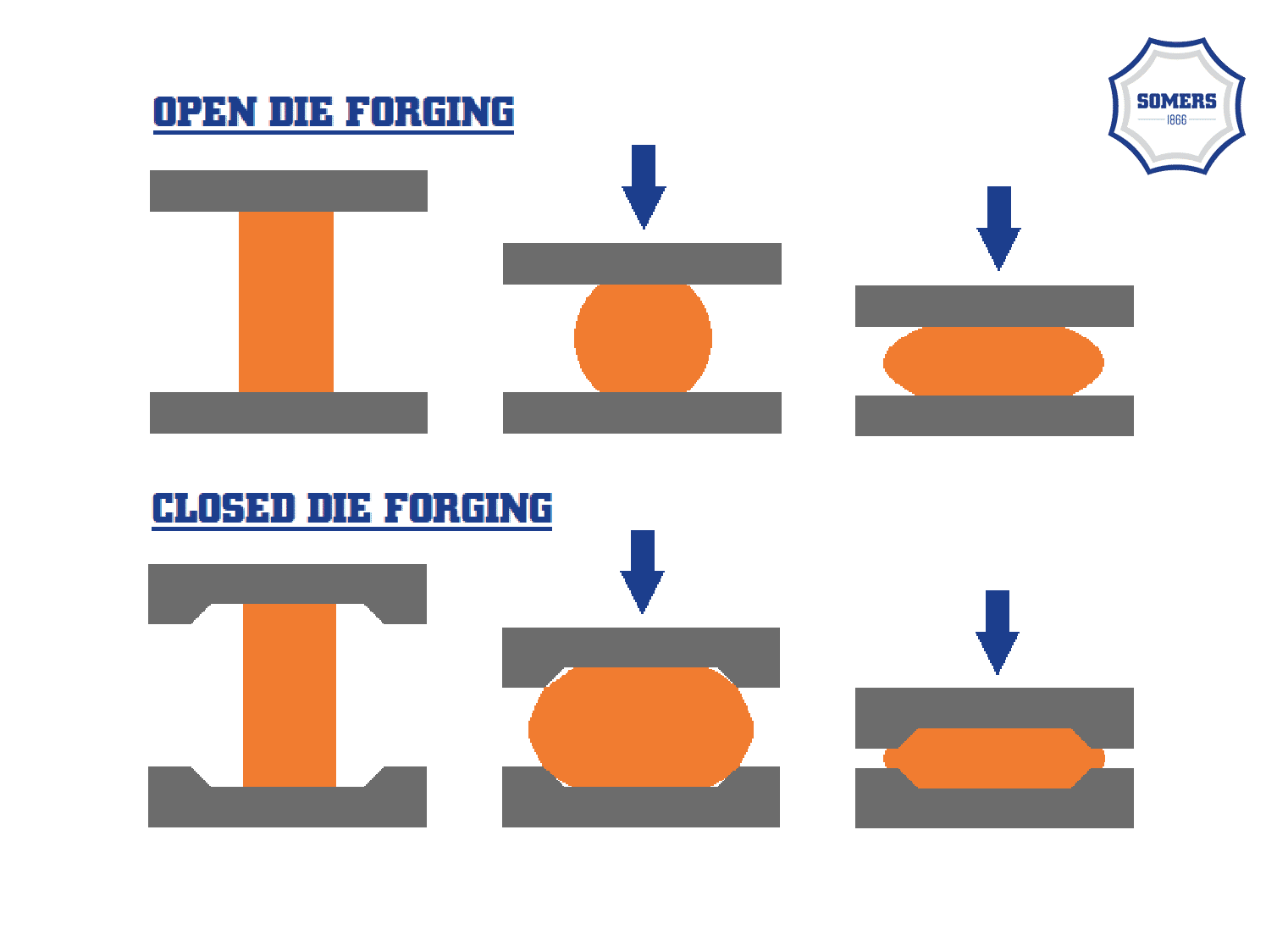

A wide-range of open die forgings are offered here at Somers Forge. Open die forging is the process of shaping heated metal between a top and bottom die using force.

The term open die gets its name from the work-piece not being enclosed. With each continuous strike of the metal, it is gradually shaped to the required dimensions increasing the strength and grain structure.

Skilled operators are essential, as they control the movements to gradually achieve the desired shape through repeated hammering.

Items are manipulated at high temperatures normally ranging from 1200 -1280 degrees centigrade. However, it is not possible to form high precision parts from just the forging process alone; the machining of products after forging is often required to achieve the desired finish.

Our unique forging equipment is capable of forging close tolerances to minimise the amount of machining required on a finished part.

In-turn, this helps to minimise tooling costs, making open die methods more cost-effective for small production runs and one off pieces. It is particularly suitable for businesses seeking flexibility and high quality results on a smaller scale.

Closed die forging on the other hand has dies which are specifically shaped to the desired configuration, resulting in high costs to make the tool mould before adding on the forging cost itself.

The open die forge does not enclose the metal completely and therefore allows different dimensions to be created with greater properties/scope unbeatable grain structure.

What types of applications are best suited to open die forging?

Open die forging is best suited to large pieces used for short runs. These mostly consist of forged bars, blocks, shafts, cylinders, discs, hubs, flanges and custom forged shapes.

Most popular applications are often single runs or bespoke designed items. Its versatility in shaping custom and large-scale components therefore makes it the preferred choice for industries requiring flexibility and adaptability in their manufacturing processes.

Critical industries that benefit most from

open die forgings methods include:

• Defence

• Marine

• Power Generation

• Nuclear

What is the difference from closed die forging?

Closed die forging, also known as impression die forging, is a process where heated

metal is shaped within the confines of two precision-engineered dies. Unlike open die

forging, the material is compressed and moulded into the exact dimensions of an

enclosed die impression.

Closed die forging therefore excels in crafting intricate parts

with tight tolerances. However, due to the tools and specialised machinery required,

initial costs to produce these dies are high, and so open die methods are favoured for

small runs and one off pieces.

What are the benefits of open die forging over closed die forgings?

As closed die forging uses dies which are specifically shaped to the desired

configuration, it results in high initial costs to make the tool mould, before then adding

on the forging cost itself.

Open die forging on the other hand does not enclose the metal

completely. This allows different dimensions to be created with greater

properties/scope, unbeatable grain structure, whilst also keeping costs low.

Greater Strength:

The repeated deformation during the forging process enhances the

metal’s grain structure, resulting in superior strength.

Improved Microstructure and fatigue-resistance:

The forging process improves the metal’s durability. This makes it ideal for components subjected to stress and fatigue over time, increasing the lifespan of the piece.

Finer Grain Size:

Refined grains allow metals to deform more evenly under stress, leading to improved ductility as well as allowing for a better surface finish during

machining.

Reduced Voids and defects:

Unlike closed die forging, open die forging minimises the risk of voids, which are common in metals formed during the solidification process.

Economical for short runs:

Since there are no tooling costs involved, it is more cost-effective for producing small quantities and one off components.

By subjecting the metal to repeated pressure, the process enhances structural integrity

and grain flow, thereby reducing porosity and improving strength, durability, and fatigue resistance.

Moreover, open die methods offer quick lead times, making it economically viable for various industries without the need for bespoke tooling.

What are the disadvantages of open die forging?

Limited Precision for Complex Shapes:

Open die methods are less effective at creating intricate or highly detailed shapes

compared to closed die forging, which excels in achieving tight tolerances and

precision.

Additional Machining:

To achieve exact dimensions or a polished surface finish, open die methods often

necessitate post-forging machining, unlike closed die forging, which minimises this

requirement.

Despite these limitations, open die methods offer unparalleled flexibility and cost

effectiveness for small production runs and custom designs.

Open die forging materials

Here at Somers Forge, we have the capacity to forge a large range of materials including:

- Carbon steel

- Alloy steel

- Stainless Steel

- Inconel

- Titanium

- Tool steel

- Aluminium

- Copper

- Nickel

- Bronze

Find out more about our forged products and our steel stockholding.

Why Somers Forge for Open Die Forging Solutions?

At the core of Somers Forge is an unrivalled commitment to precision and detail. Whether it’s a specialised part, a limited edition run, or a product requiring specific characteristics, we are experts at tailoring solutions to the individual needs of our customer base spanning many different industries.

Our team of seasoned and skilled professionals, dedicated to the perfection of their craft, ensure that every product is forged to meet exact specifications, making us the premier destination for all your open die forging solutions.

Need help? Contact the experts

If you are still unsure which forging process to use for your business or have any other

questions, here at Somers we are happy to answer any queries. Please

contact us on 0121 585 5959 or email at sales@somersforge.com.

Contact Us

Useful Links

Forged Products | Steel Stockholding | Open Die Forging | Open Die vs Closed Die