What are Forged valves?

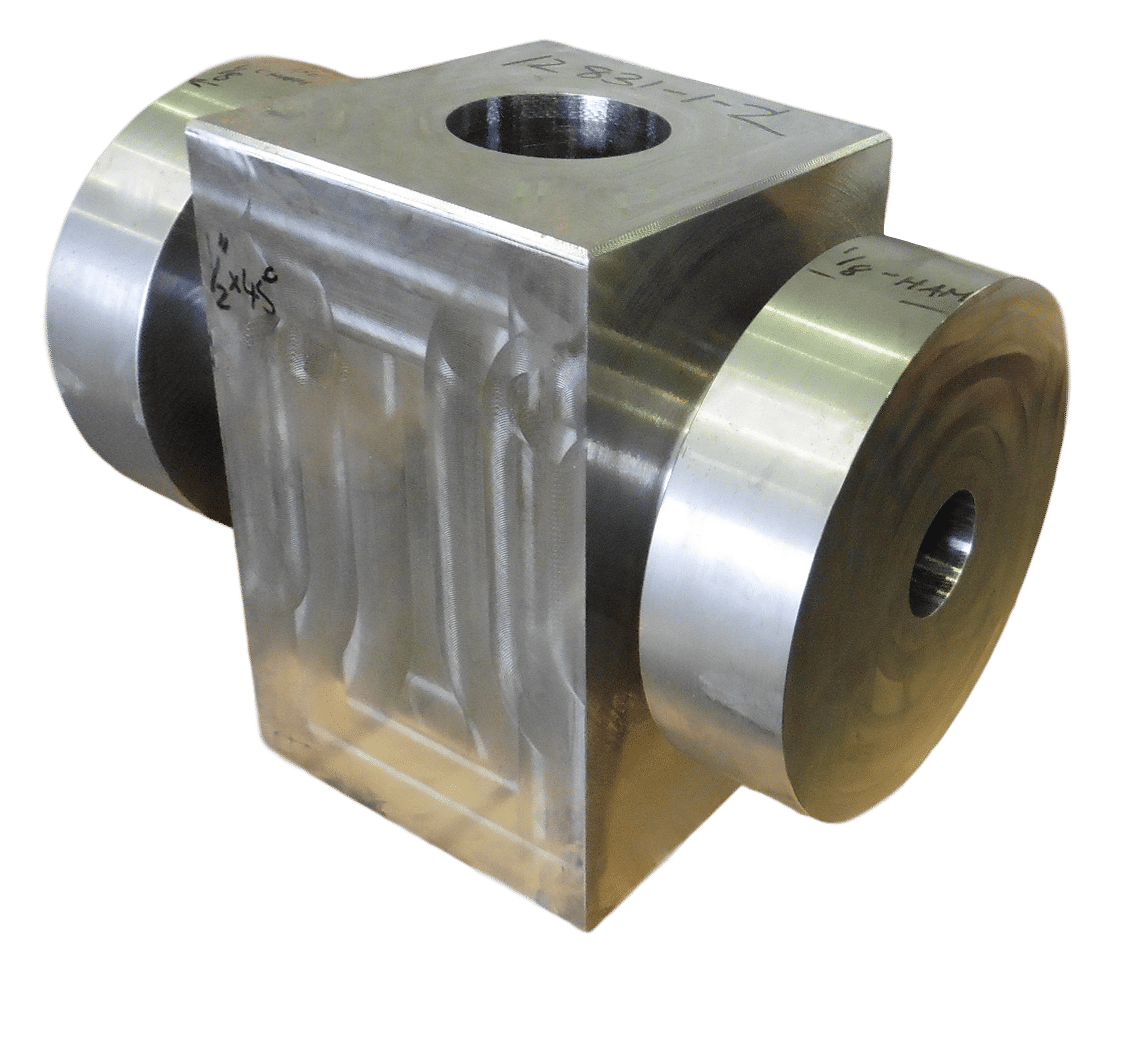

Forged valves use a forging process to shape metals and alloys in their solid form. With the valve body being forged as one solid piece, there is very little wasted material to achieve the shape. Dies and tools are then used to cut and shape the materials to create valve bodies. These valves are then usually used to start, stop or throttle the flow of liquid or gas, ensuring the highest safety and efficiency throughout.

Valve body forgings are primarily used in the oilfield industry applications and are often made from high specification/high-grade alloy materials. This requires the valves to be durable, with the operating environment being extreme and critical, making longevity key for forged values. The design of valves can be very intricate as they invariably fit into high pressured multi-part applications. This favours high-end alloys and stainless materials, whilst being durable they can also interact with other moving components both seamless and safety.