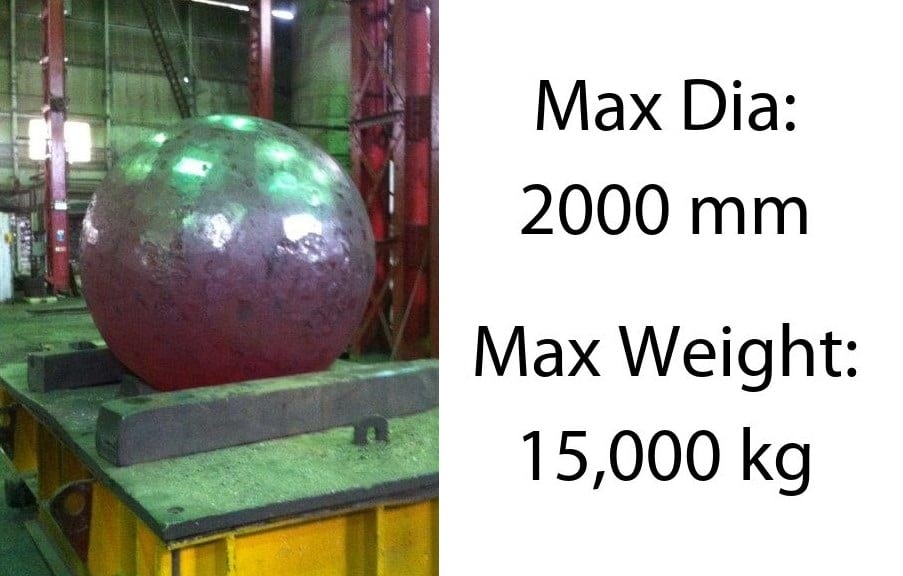

For many years Somers Forge have supplied high integrity forged drop / breaker balls, to both the mining and metal reclamation industries. Our products can be found operating in many countries across the world, successfully working in extreme conditions.

Somers have refined the chemical analysis of the material used in manufacture of our drop / breaker balls, which improves impact properties at ambient and sub-zero temperatures.

Raw material is melted to an exact specification which includes electric melting and vacuum degassing with hydrogen levels below 1.5 PPM at pouring which alleviates hydrogen de embrittlement.

During the forging process material is subject to a minimum forging reduction of 3-1. Immediately after forging we perform a secondary de gassing operation and an additional normalising heat treatment to refine the grain structure.

Fully forged balls have an advantage over cast alternatives with a fully homogeneous fine grained structure offering additional toughness and ductility resulting in less failures during service.

To enquire about breaking balls, simply fill out the form on the contact page today.